Start with the ‘why’: Before starting your route selection process, it is important to ask the following questions:

By fully understanding your objectives, we will be able to design and develop the most appropriate route for your API.

It is key to generate a wide range of ideas when designing a new synthesis. To ensure that all ideas have been explored, we follow three streams:

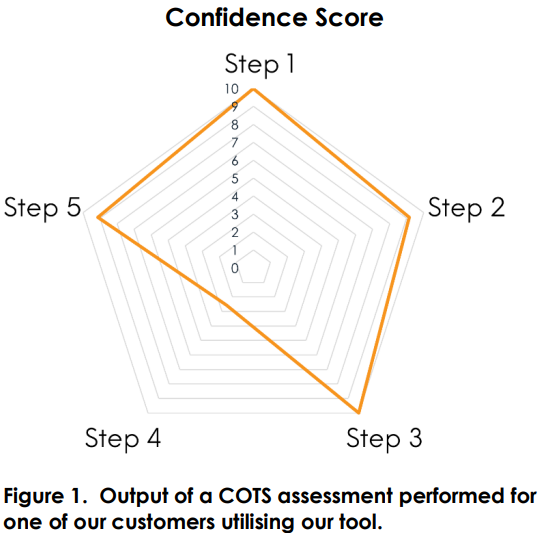

The most critical part of any new route selection is predicting the Chance of Technical Success (COTS). Our internal tool drives a rigorous, objective assessment of all routes and predicts a score for COTS of each route. The benefits are:

Diagram 1 shows an example of a COTS measurement output. For this 5-step synthesis, we had very high confidence in 4 of the steps working well, driven by literature precedent and internal knowledge. It was clear that step 4 carried more risk; this understanding helped us to drive an efficient strategy to rapidly prove the viability of this route.

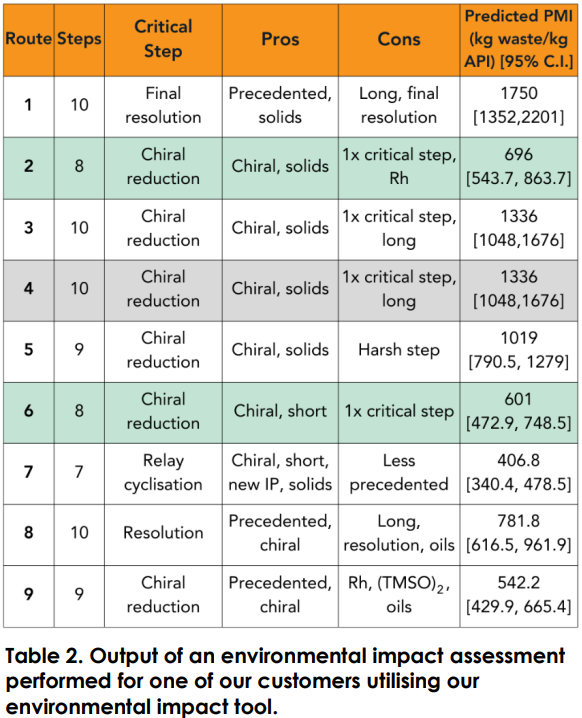

Until a process has been developed, it is not possible to give an accurate figure for environmental impact. However, we can predict the PMI factor of each route by utilising a tool developed by the ACS Green Chemistry Round Table. Some of the factors that the tool assesses include:

The tool has been shown to give a reasonable correlation between predictive and actual values. As well as a predicted PMI, we also highlight any specific reagents or intermediates which may not be ideal from an environmental or safety perspective.

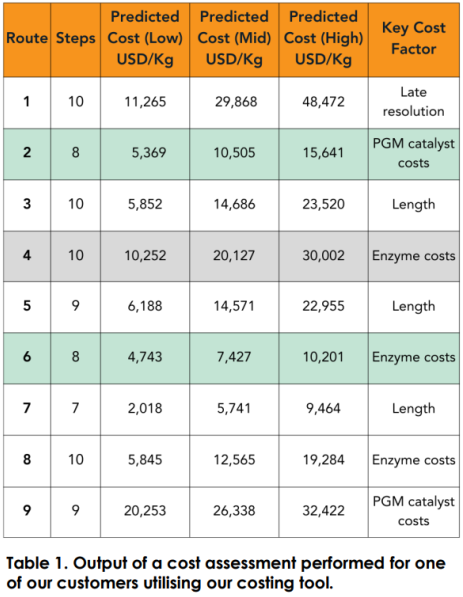

At the on-paper route ideation stage, it is not possible to ascertain an exact cost for the synthesis of a molecule. As such, we developed a simple costing tool that allows us to build relative and indicative costs for each route. We do this by considering:

If we understand more about where you may want to manufacture material and commercial volumes, we can adjust some parameters to give a closer estimate.

Try our free route costing calculator to estimate the cost of your materials and operations, along with the total cost of each step and the entire route.

Planning – Idea Prioritisation

We prioritise the generated ideas based on the phase of development that the project is in, and any specific requirements that the customer highlights.

For Early Development projects, we look at:

For Late Development projects, we look at:

Planning – Resource Requirements

We develop a plan based on the required resources, focusing on:

Once an agreed plan has been developed, the next step is to practically demonstrate the chemistry. We deliver this by leveraging our expert team, state-of-the-art facilities, and Ways of Working.

Expert team and state-of-the-art facilities:

WoW

Our CMC experts employ their diverse technical backgrounds and end-in-mind approach to generate a wide range of high-quality ideas tailored to your API’s development phase, timelines and unique requirements in terms of safety, cost, regulatory compliance, sustainability and IP.

We have developed a suite of industry leading tools that objectively assess any synthetic route across several areas, including Cost of Goods, Chance of Technical Success, environmental impact and resources required. This structured and unbiased approach ensures that you select the right route for your API.

After working closely with you to prioritise the generated ideas and create a plan based on your specific requirements, we practically demonstrate the chemistry, establish proof of principle and perform a demo batch. This is done within our state-of-the-art laboratories supported by a dedicated team of chemistry, analytical and solid-state experts.

A dedicated technical project leader responsible for project delivery will provide you with updates in the format and cadence that suits you. We actively seek regular feedback from you to ensure that your voice is heard and expectations are met. Upon project completion we will deliver a detailed tech transfer package and can oversee its implementation with your manufacturing partner.

Check out our whitepaper to find out how we help our customers to improve the scalability, robustness, safety, efficiency, commercial viability and sustainability of their processes.

Work out the cost of your synthetic route with our free, easy-to-use cost calculator

The CatSci team was tasked with designing a cost-effective and commercially viable synthetic route for a highly complex chiral molecule in late development to support market access.

To solve our customer’s challenge, the CatSci team employed our industry leading route scouting and selection workflow and tools:

Though our structured and unbiased route scouting approach, innovative WoW, state-of-the-art labs and CMC expertise we successfully developed a cost effective and commercial viable synthesis: