Capabilities

End-to-End Expertise Across

Every Modality

Spanning small molecules to oligonucleotides, peptides, and hybrid modalities, we unite chemistry, bioscience, and analytics to accelerate the development of complex synthetic medicines from discovery to IND and beyond.

Drug development isn’t a standardised process, and modality-specific challenges rarely fit generic solutions.

Each class of molecule presents distinct synthesis routes, purification hurdles, stability risks, and regulatory expectations. Overlooking these nuances can delay progress, increase costs, and jeopardise quality.

At CatSci, we offer tailored, end-to-end support aligned to your modality, development stage, and commercial objectives. Whether scaling a known class or building a novel platform, we help you move with scientific clarity and operational control.

Our oligonucleotide experts unite chemistry and analytics to accelerate RNA-based therapeutics. From sequence design to conjugation, they deliver decision-ready data and scalable solutions for siRNA, ASO, and emerging nucleic acid platforms.

Specialists in complex peptide synthesis, modification, and purification, our team create high-quality linear, cyclic, and stapled peptides. They combine deep chemical insight with analytical rigour to deliver stability, purity, and performance in every sequence.

Our targeted protein degradation scientists bring together expertise in bifunctional design, linker chemistry, and biological testing. They turn complexity into robust process understanding - engineering degraders and molecular glues that are stable, scalable, and ready for development.

At the intersection of chemistry and biology, our hybrid modality scientists develop conjugates and multifunctional platforms that expand the therapeutic potential of these molecules. Our integrated approach ensures structural control, stability, and delivery across modalities.

Our small molecule scientists design and optimise scalable, efficient routes that balance innovation with manufacturability. Our expertise spans route scouting, process chemistry, solid-state science, and HPAPI development, delivering chemistry that performs from lab to launch.

Our scientists excel at bridging modalities, integrating small molecule, peptide, and oligonucleotide expertise to develop hybrid constructs and next-generation therapeutics. They thrive on solving the challenges that sit at the edges of chemistry and biology.

Our catalysis experts push synthetic boundaries using biocatalysis, hydrogenation, and flow chemistry to streamline complex transformations. They design elegant, sustainable solutions that enhance selectivity and scalability.

We design and deliver robust, decision-ready biological assays, from target engagement to phenotypic models, giving you the clarity to move your programme forward with confidence.

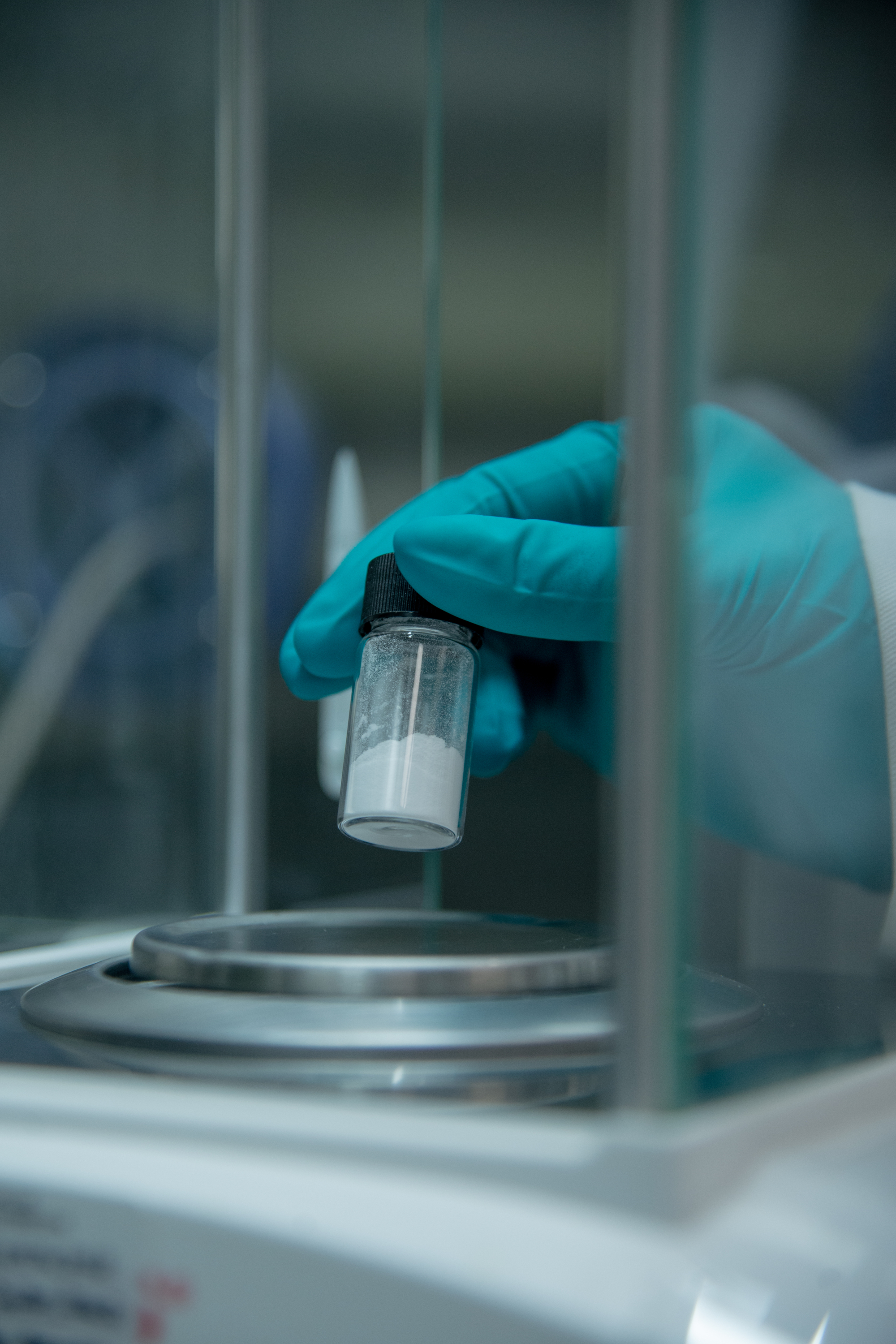

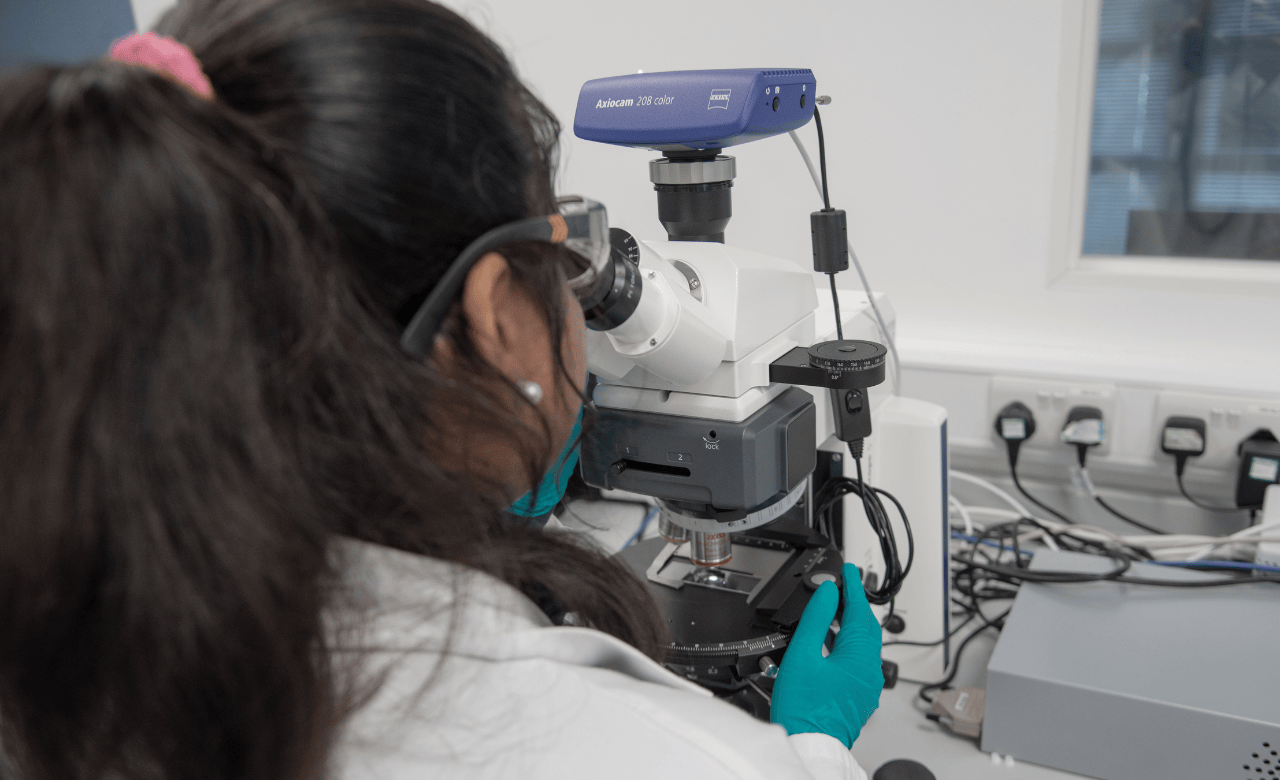

Our analytical scientists ensure every molecule is understood, controlled, and compliant. From method development to ICH validation, they provide the clarity and confidence that underpin every stage of CMC development.

Our route design specialists define efficient, cost-effective, and sustainable synthetic pathways from the start. They combine retrosynthetic insight with green chemistry principles to de-risk your project and accelerate scale-up.

Experts in preparative chromatography and chiral separations, our purification scientists deliver the purity, yield, and reproducibility that move programmes forward. They work seamlessly across modalities to isolate excellence in every batch.

How We Work Across Modalities

Early route ideation, chance of technical success planning, costing and retrosynthetic analysis, and sustainability modelling inform smarter decisions before scale-up begins.

Connected chemistry–biology integration accelerates hit-to-lead optimisation and IND readiness with iterative, data-driven insight.

Our teams in chemistry, bioscience, purification, and analytical development collaborate seamlessly, maintaining a single scientific thread across your project.

Specialised chromatographic and SFC strategies designed for your molecule’s specific profile and development needs.

Holistic, cross-modality strategies that unify discovery and development through shared data, tools, and decision frameworks.

Every project is planned with the final goal in sight: from process scalability and stability to regulatory and commercial readiness.